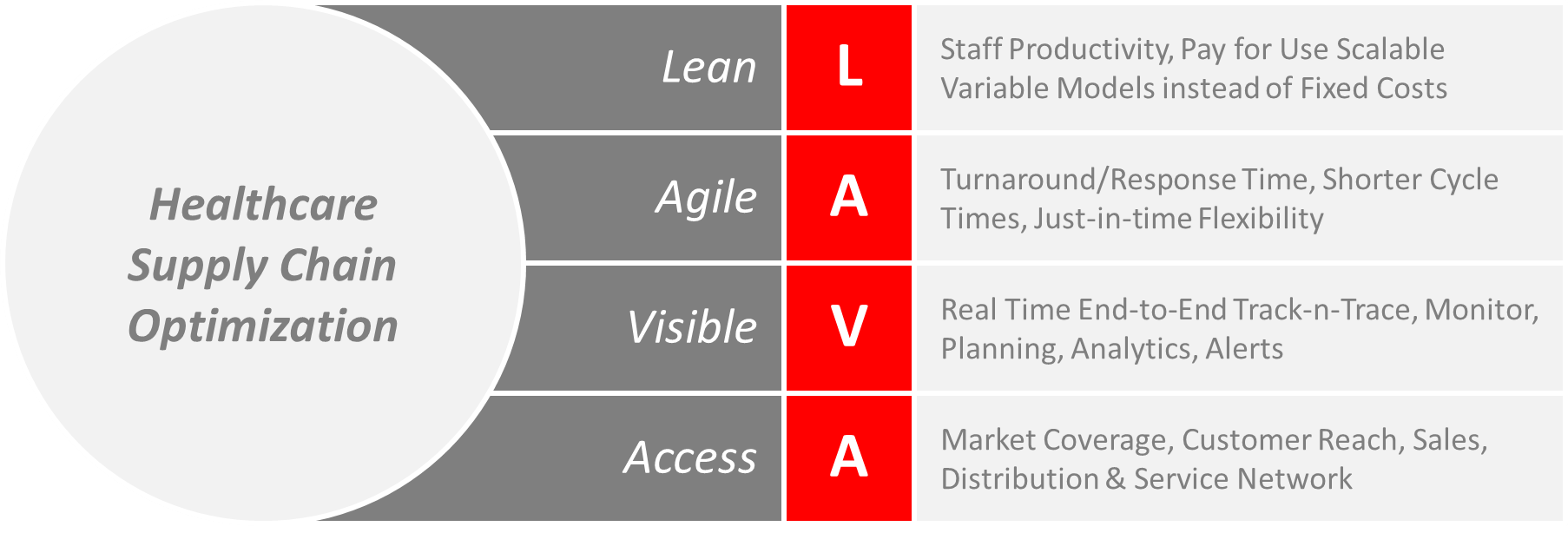

Industry Needs Lean Agile Visible Access

Resolving radical challenges requires radical responses.

Dynamics: Rising Supply Chain Complexities

- Supply chain constitutes 30%-60% of hospital expenses.

- Some implantable devices constitute 25%-75% of the overall surgery cost.

- Device prices are 300%-800% of the manufacturing/ import cost.

- Over 99% of device brands sell below INR 100 crores p.a.

- Over 80% of hospitals are below 30 beds - over 95% doctor/ surgeon-owned.

- Over 70% of the medical devices are imported.

Affordability is challenged at every market point, despite the growing, yet lagging medical coverage.

Gaps: Opaque, Expensive & Inefficient

- Buyers have limited visibility of options and sellers have limited reach and coverage.

- Many small pockets of revenue challenge distribution point feasibility.

- Over 50% of sales time is wasted on administration.

- Manual, inefficient processes lead to substantial duplication and rework.

- Unpredictable demand of the ever-expanding portfolios requires a high degree of just-in-case preparedness.

- SKU-specificity requirement puts loads on inventory-holding levels.

Top this with the mounting patient safety, quality and compliance requirements, it is becoming imperative to ensure traceability for recalls; for tracking expiry and obsolescence; or to combat infiltration of counterfeits. All this is adding cost at every leg of the chain due to unproductive deployment of resources, staff, inventory, logistics, infrastructure, working capital, debt-servicing etc.

Cause: Unattainable Economies

Scale is a barrier to optimise costs, productivity, specialization, network design, automation and more. Disjointed IT-systems render a broken supply chain - impacting controls and assurance, better decisions faster and heightens the trust-deficit. Disjointed distribution structures are a further barrier to optimize inventory holding and movement; besides adding costs that adversely affect margins and market price. Workflows are not standardized and hence consume expensive interventions at transactional levels to gain alignment amongst trade partners. Also, alongside the deep fragmentation, the increasing dispersion to smaller and remoter markets is further compounding the complexities in healthcare supply chain.

Need: Lean Agile Visible Access

Optimize the supply chain to cut costs, save time, reduce complexities and prevent errors:

- From manual, inefficient workflows to process automation and standardization;

- From silos of disjointed IT systems to an integrated automation platform and real-time visibility;

- From significant duplication and rework to networked syncs, scans, status;

- From disjointed distribution structures to unified supply chain networks;

- From paperwork/ calls/ posts/ faxes/ emails to electronic data exchange (EDX);

- From costly stocking and logistics to savings from collective scale and space-on-demand arrangements;

- From limited footprint and feet on street to extended reach and online connect.